The need to be competitive with other modes of transport has obliged the railways to look further into solutions to make it more efficient, mainly in reducing the costs related to infrastructure maintenance.

The use of ballastless track, with a higher initial cost than ballasted track, has been touted as a solution to the high maintenance costs of railways, although experience has shown that this has not always been the case. In the field of ballastless track, there are other recent alternatives based on the use of polymers and geomembranes to provide greater elasticity to the infrastructure, although they are still in the research phase.

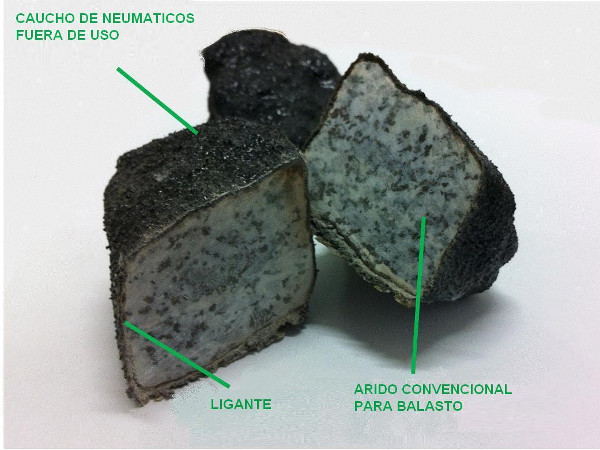

In response to these problems, a project is being developed to coat ballast aggregates with rubber powder from end-of-life tyres (NEOBALLAST®) in order to reduce deterioration and reduce the vibrations and noise generated by passing trains.

This improvement is achieved through an increase in particle contact area and a reduction in the stiffness of the ballast as a whole.